Vol. 1 / Issue 6

Print Tips: Digital vs. Offset Printing

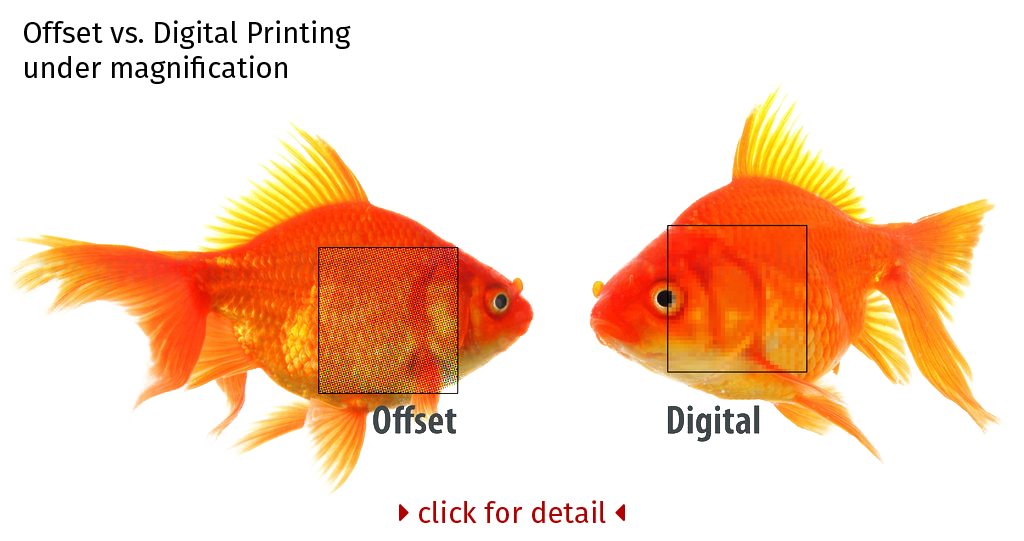

For prospective print customers, the difference between offset printing and digital printing is that digital printing is better suited for short run printing (i.e. starting at 1 single copy) and offset printing is better suited for higher volume printing.

For prospective print customers, the difference between offset printing and digital printing is that digital printing is better suited for short run printing (i.e. starting at 1 single copy) and offset printing is better suited for higher volume printing.

Both types of printing produce print products that are extremely high in quality and fit for professional quality printing for businesses. The key factors that make customers choose one over the other is typically the volume of the print project and niche project requirements.

So let us begin by outlining the differences between the two types of printing...

Offset Printing

Lithography was developed in 1796 by Alois Senefelder as a cheap method of publishing theatrical works. However, it wasn't until 1875 that modern offet printing was developed by by Robert Barclay and then refined by Ira Washington Rubel in 1904.

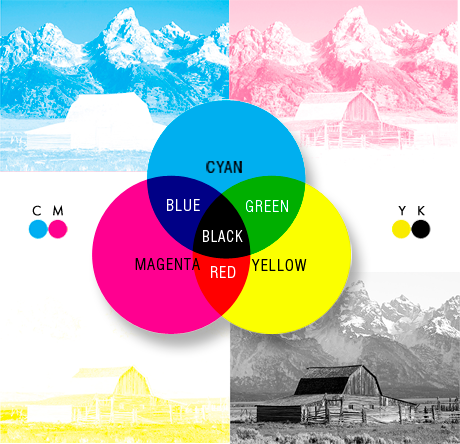

Offset lithography is the most commonly trusted high volume commercial printing technology. In offset printing, the design image is first burned onto a plate, and is then transferred (or offset) from the plate to a rubber sheet, and finally to the printing surface. The lithographic process is based on the repulsion of oil and water. The image to be printed gets ink from ink rollers, while the non printing area attracts a film of water, keeping the non printing areas ink-free.

Digital Printing

If you have a desktop printer at home, you’re likely already familiar with the mechanical process of digital printing. As the new kid on the block, it wasn't until the 1990's that digital printing started to become commercially available. Many of the steps required for offset printing are eliminated. Namely, making films and color proofs, paper waste, manually stripping the pieces together, and making plates; which results in a much more affordable print solution. Digital presses, laser printers and photocopiers do not use ink but instead use toner. Toner is a powder that is used to form the printed text and images on the paper. In its early form it was a mix of carbon powder, iron oxide, and sugar. Then, to improve the quality of the printout, the carbon was melt-mixed with a polymer.

Pros & Cons of Digital & Offset Printing

DIGITAL — The Pros:

- Fast, allowing for shorter turnaround times

- Lower costs for small print runs

- Availability of variable data printing (database driven, e.g. mailing lists)

- Output is printed on both sides, dry and ready for any bindery work

- Can print direct on envelopes

- No paper waste

- Can print on synthetic paper.

DIGITAL — The Cons:

- Uses toner cartridges, not ink.

- Dark inks sometimes appear glossy.

- Cannot print on stock under 50# or on stock over 130#.

- Sheet size is limited to 13" x 19"

OFFSET — The Pros:

- Higher image quality, higher resolution and no streaks/spots.

- Works on a wide range of printing surfaces including paper, wood, cloth, metal, leather, rough paper and plastic.

- Quality and cost-effectiveness in high volume jobs.

- Many modern offset presses use computer-to-plate (as opposed to the older computer-to-film system) further increasing quality.

- The finished printed piece can go back through a customer’s laser printer.

OFFSET — The Cons:

- Only cost effective for large runs.

- Takes more time to setup for print vs digital.

- Accurate proofing and multiple changes can be very expensive.

- Paper waste for setup

Some Final Thoughts on Printing

1. Leave Nothing to Chance

Be very specific with your print company when communicating which stock you want used, which colors, which process (digital vs offset) and what sort of finishing or coating you want on the finished product.

2. Get Samples

Before initiating your print project, request samples from your prospective print companies. All reputable print houses have a standing offer of free samples expressly for this purpose.

3. Always Proof!

If you are managing your own print project, and are working with a local firm, be sure to request a pre-press proof before authorizing the full run. This will allow you to confirm that the company understood your specific instructions outlined in item 1 above. It will also allow you a hands-on preview of the final product, so you can catch any imperfections ahead of time. If you are working with a remote partner, be sure to request a digital proof… while this requires an element of trust in terms of the stock and finish, a digital proof will allow you to ensure all visuals are to spec.

In the end, a good design cannot fully live up to its potential when run on a shoddy print job. If you are as careful and selective in choosing a print partner as you were in choosing a design firm, you can ensure that the physical product that actually reaches your partners or customers is of the highest possible quality. Because all things considered, high quality is precisely the message you want to deliver. Call, email or stop by today and let us help you with your printing needs.

Some helpful links

[ https://en.wikipedia.org/wiki/Lithography ]Wikipedia's page on Lithography.

[ https://en.wikipedia.org/wiki/Offset_printing ]

Wikipedia's page on Offset Printing.

[ https://en.wikipedia.org/wiki/Digital_printing ]

Wikipedia's page on Digital Printing.

Phone: 734-663-6816 • Toll-free: 800-696-9627 • Email: Info@advprint.com